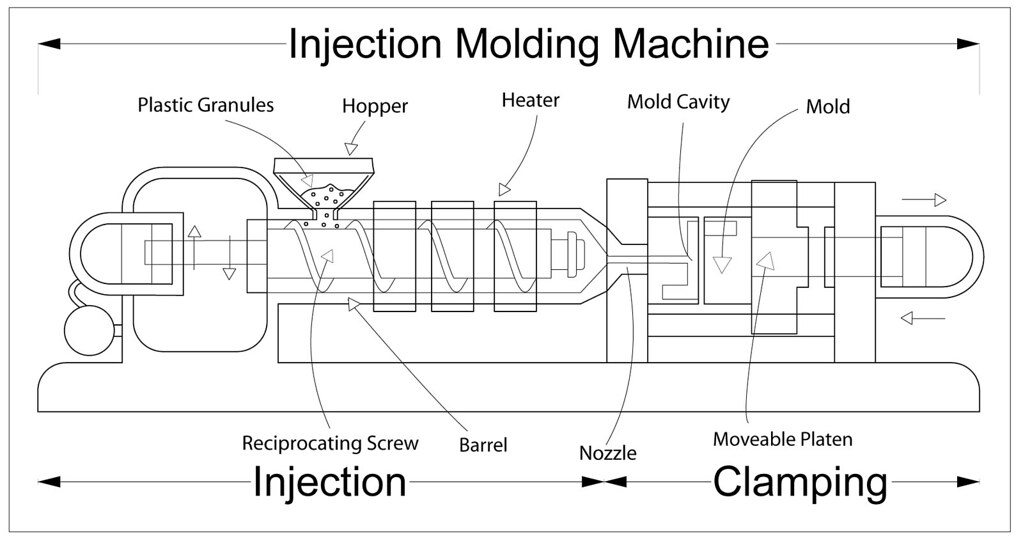

In the last post we discussed the origin of plastic

products. Now, We will move a little deep into the manufacturing

process. We came to know that for plastic production, plastic injection

moulding was used.

1847 First condensation polymer (polyster) was produced by Jons Jacob Berzelius.

1861-62 Alexander Parkes invented first

man-made commercial plastic Britain. He named it Parkesine. It was

expensive to produce, brittle and flammable, but it could be heated,

moulded and used to retain its shape once cooled.

1868-72 John Wesley Hyatt developed Celluloid,

a plastic material made from a process that combined cellulose nitrate

and camphor. It was an improved version of parkes invention. Hyatt also

patented the first injection molding machine.

1909 Leo Hendrik Baekeland discovered Bakelite.

1930-37 Vinyl thermoplastics such as polystyrene, PVC and the polyolefins were developed.

1938 Dow invented Polystyrene plastic, which is still used widely today.

1939 A massive demand for cheap, mass-produced materials was generated during Second World War.

1941 Nylon was being used as a moulding material.

1945-1955 Gradually, Polyethylene and

polystyrene started replacing are older materials such as metals, woods,

leather and glass. Also, during this time, First extrusion screw

injection machine was built by American inventor James Watson Hendry.

1955 General Electric entered the market with Polycarbonate.

1955-65 High-density polyethylenes and discovery of polypropylene were major developments of this period.

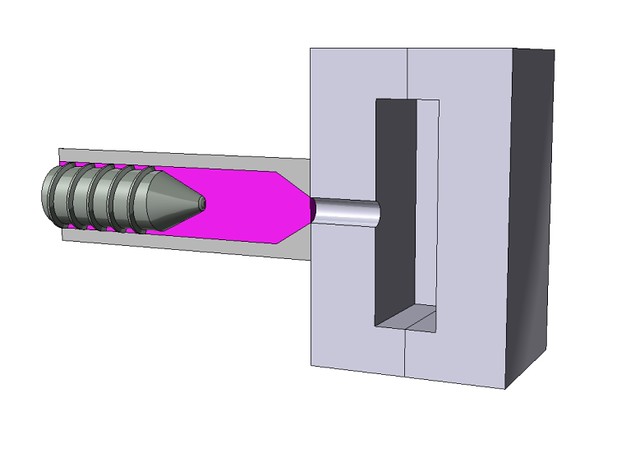

1956 Patent was issed to W. H. Willert for reciprocating screw plasticator machine.

1960s Polysulphones, the PPO-type materials, aromatic polyesters and polyamides introduced.

1970s First gas-assisted injection molding

process was developed by James Watson Hendry, which permitted the

production of complex, hollow articles that cooled quickly. This greatly

improved design flexibility as well as the strength and finish of

manufactured parts while reducing production time, cost, weight and

waste.

1972-79 Plastic production overtakes steel production.

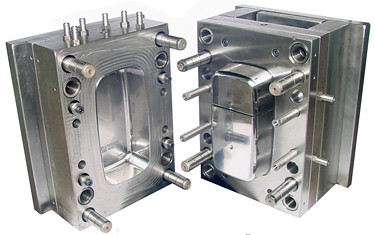

1990 Aluminum molds first used widely in injection molding.

Latest trends in Injection Moulding:

There are a number of significant developments in custom injection molding

technology. These developments involve CAE (Computer Aided Engineering)

including the prediction of the properties of molded parts, innovative

experiments to analyze processing, new machineries (processing) and

recycling plastics.