If you are looking for Plastic Injection Moulding

Manufacturers in Brisbane, then it is not a challenging process. You can

quickly bring all the details from the web. But validate the stability

before any purchase. Though online is an easy resource to find the

details but is a home for many frauds too. You have to get on your tip

of toes to search for top high quality products.

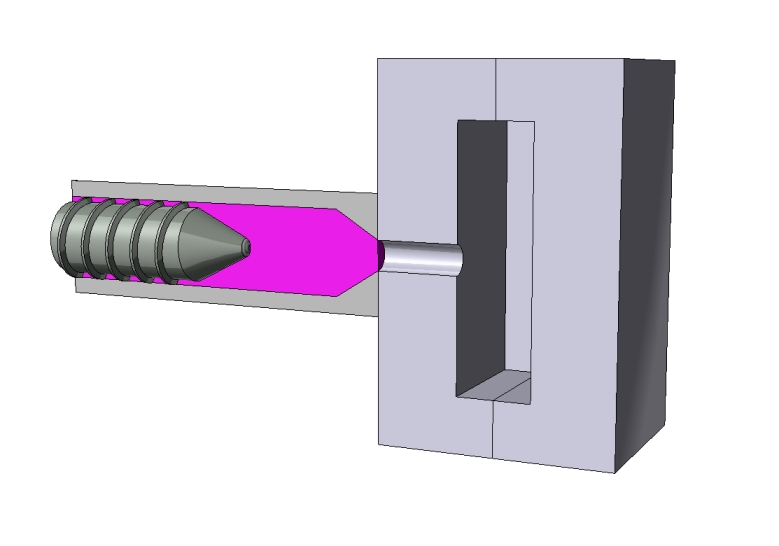

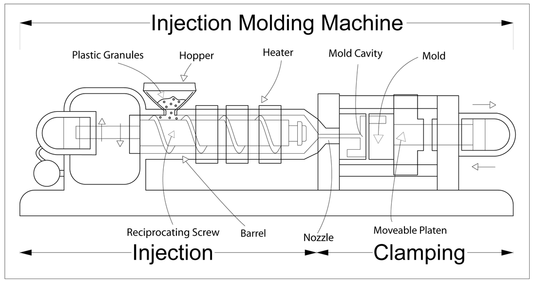

Injection Moulding Brisbane is one of the most

typical procedures for plastic materials production. Make sure you

discuss to the manufacturer about the kinds of procedures they have.

There are also many kinds of injection moulding. Make a price comparison

on the different types and discover out which one will fit your item

best.

If you don't stay anywhere near any production

company then you can have a look on the internet to try and discover

some solutions that'll be appropriate for your needs. There are a lot of

plastic moulding services available, both off-line and online so you

must not have too much problems finding what you need.

Just make sure that you do a lot of analysis before

you commit to anything because it can sometimes be a bit complicated and

you don't want to end up with factors you don't need. Also, it's

essential to know what you're looking for so that you don't get

attractive off.

If not the whole but at least you have to get the

basic information about plastic before approaching any of the plastic

manufacturers. Like plastic moulding is widely used for large parts such

as panels of the vehicle body. Usually the parts are created from

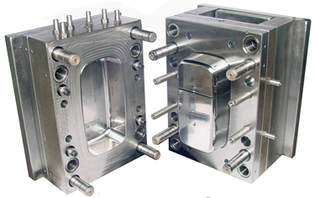

thermosetting. Injection Moulding Brisbane is another type. It is a very

easily understood process that includes extreme heating of the

thermoplastic and then it is molded. The mold is often made up from the

ceramic. It is usually used in making consumer items like fridge

containers, tubing and toys.

Taking simple factors like this in to consideration

will help ensure you get the best high quality services related to

plastic injection moulding and choosing a company that will provide top

high quality products for the entire order. Always look in to building

long term relations with suppliers as it also help improve high quality

distribution over the long term.

Visit Longara Plastics for more information regarding why this company is one of the top custom plastic injection moulding company Brisbane.

As one of the leading and Best Plastic Injection Moulder, We continue

to provide its customers with products and services that meet and exceed

expectations. Contact Longara Plastics today!